-

Shrimp Deheading Machine

-

Shrimp Peeling Machine

-

Shrimp Grading Machine

-

Fish Grading Machine

-

Shrimp Cooking Machine

-

Shrimp Cutting Machine

-

Shrimp Cleaning Machine

-

Fish Skinning Machine

-

Fish Cutting Machine

-

Fish Slicing Machine

-

Fish Gutting Machine

-

Fish Washing Machine

-

Fish Scaling Machine

-

Basket Washing Machine

-

Soaking Machine

-

Shrimp Processing Machine

-

Fish Processing Machine

1.5KW Practical Shrimp Peeling Machine Fully Automatic Durable

| Keyword | Fully Automatic Shrimp Shelling And Gutting Machine Shrimp Shell Separator | Material | Stainless Steel 304 |

|---|---|---|---|

| Dimension(L*W*H) | L1040xW930xH1300mm | Production Capacity | Max70Pcs/Min |

| Voltage | 220v | Power | 1.5KW |

| Weight | 230 KG | Shrimp Peeling Specification Range | 21/25 TO 61/70 |

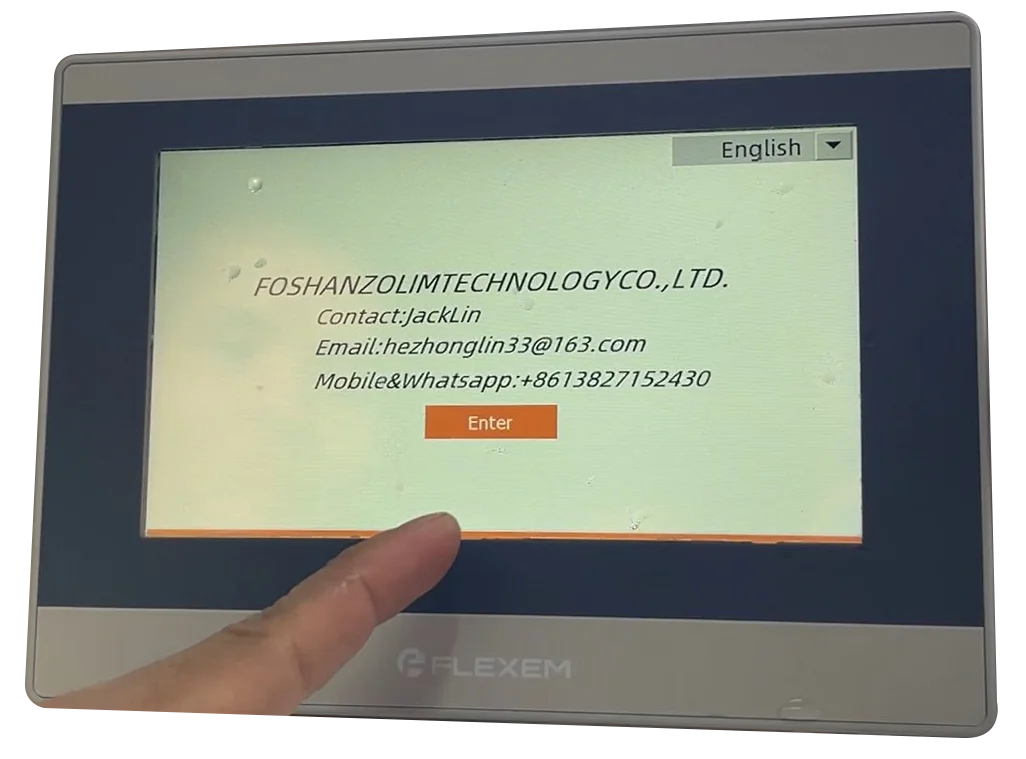

| Touch Screen | 7 Inch/Color IP65 | Brand | Zolim |

| Highlight | 1.5KW Shrimp Peeling Machine,Practical Shrimp Peeling Machine,Automatic Shrimp Shelling And Gutting Machine |

||

Fully Automatic Shrimp Shelling And Gutting Machine Shrimp Shell Separator

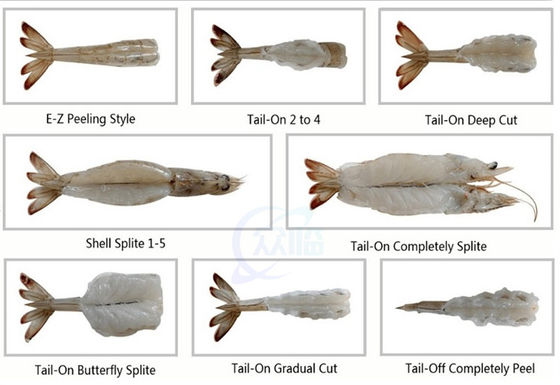

Shrimp peeling machine is a machine that can automatically peel and deveining. This product has many advantages,such as, occupies a small area, computer control, PLC touch screen setting, easy operation, can maximize the stability of product quality, WIFI connection can grasp the operation of the machine and assist in solving most of the problems that arise, greatly reducing the labor cost of the factory , the automatic shrimp peeling machine can handle different sizes of shrimp, such as 21/25 to 61/70, etc.; and can meet different processing specifications, such as EZ peeling, tai-on 2 to 4, tail-on deep cut, shell splite 1 to 5, tail-on completely splite, tail-on butterfly splite, tail-on gradual cut, and other types etc. This machine is made of shrimp The best choice for value-added processed products

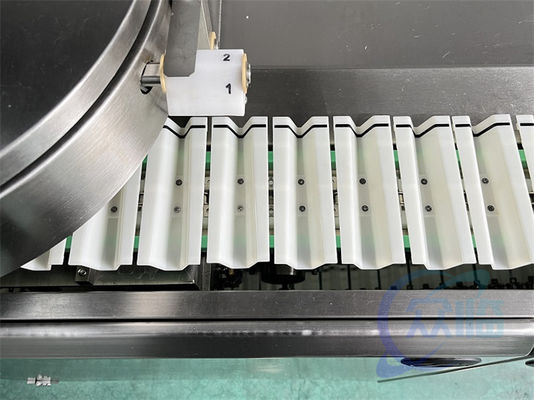

1. Cantilever mechanical structure, easy to clean and maintain

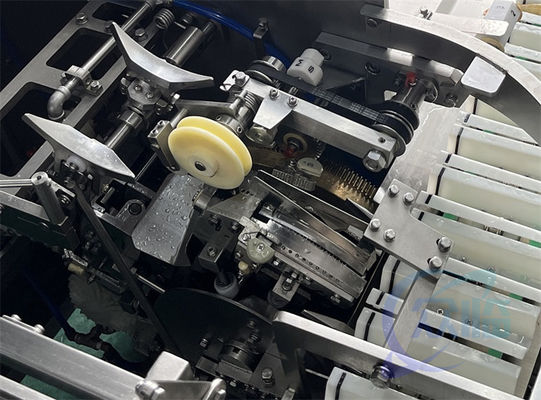

2. Servo control, reduce mechanical transmission, easy for commissioning

3.Optimized design, compatible with a variety of different forms of shrimp peeling specifications

4.User friendly HMI with memory function, easy to operate

5.IPC + servo system, easy to adjust the cutting position, cutting depth and shrimp needles forking position etc. by just changing parameters

6.A small clamp picks up a shrimp from a plastic tray.

7.The shrimp is carried through a centering guide as a large clamp closes with a firm grip on the shell.

8.If tail-on processing is selected, the body shell is broken from the tail segment.

9.The large clamp carries the shrimp through a patented cutter and guide system that precisely splits the shell.

10.A pair of brushes removes the vein.

11.A fork enters the shrimp meat, pulling it gently and cleanly from the shell.

12.The shell is then discharged at a different location.

13.After peeling, visual inspection and minor handwork complete the process