-

Shrimp Deheading Machine

-

Shrimp Peeling Machine

-

Shrimp Grading Machine

-

Fish Grading Machine

-

Shrimp Cooking Machine

-

Shrimp Cutting Machine

-

Shrimp Cleaning Machine

-

Fish Skinning Machine

-

Fish Cutting Machine

-

Fish Slicing Machine

-

Fish Gutting Machine

-

Fish Washing Machine

-

Fish Scaling Machine

-

Basket Washing Machine

-

Soaking Machine

-

Shrimp Processing Machine

-

Fish Processing Machine

Multiscene Stable Shrimp Boiling Machine , Stainless Steel Seafood Processing Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Keyword | Smart Shrimp Boiling Machine Seafood Processing Shrimp Cooking Line Steam Cooker | Core Components | Bearing, Gearbox, Motor, Pressure Vessel, Gear, Steam Valve |

|---|---|---|---|

| Material | Stainless Steel 304 | Dimension(L*W*H) | L11000xW2200xH2000mm |

| Production Capacity | 500-700KG/H | Power | 18.2KW |

| Weight | 1000KG | Be Used For | Shrimp Processing |

| Operator | 4-5 Persons | ||

| Highlight | Multiscene Shrimp Boiling Machine,Stable Shrimp Boiling Machine,Stainless Steel Seafood Processing Line |

||

Smart Shrimp Boiling Machine Seafood Processing Shrimp Cooking Line Steam Cooker

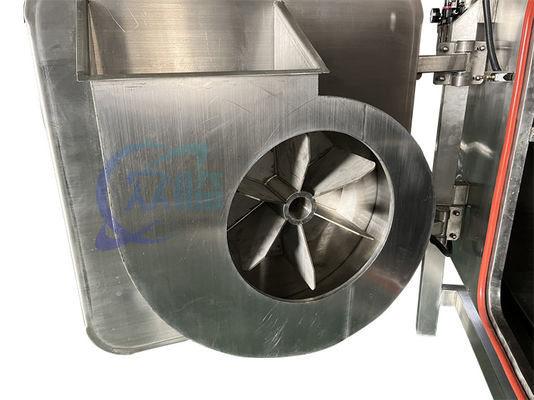

The shrimp cooking machine is a machine that uses the wind blown out by a fan to make the shrimp inside cook more fully and evenly. The steam can be automatically turned off or replenished according to the actual demand. Compared to traditional cooking machines, it achieves maximum energy conservation and consumes only 1/3 of the traditional diesel fuel consumption The cooked shrimp is more evenly cooked, the color is more beautiful, and the taste is more delicious

1. The entire machine consists of four zones, made of stainless steel 304, with a sturdy structure, stable performance, superior quality, and beautiful craftsmanship.

2. The temperature of each zone can be individually controlled, so that the boiled shrimp can achieve the best effect.

3. The speed of the conveyor belt is controlled by a Schneider frequency converter, which can be set according to the desired temperature for shrimp cooking

4. The steamer has four zones, each with a fan. After steam enters the machine, the wind blown out by the running fan makes the temperature of shrimp cooking more uniform. The steamed shrimp is even more delicious!

5. The conveyor is made of stainless steel material and plastic material, which can be customized according to customer requirements.

6. Each zone's air inlet is equipped with a control valve that can control the intake volume. When sufficient steam volume is detected, the control valve automatically closes, and when a decrease in steam volume is detected, the control valve automatically opens to replenish steam. This can maximize steam savings and truly achieve energy conservation.

7. This machine can not only cook raw shrimp, but also shrimp kernels, decapitated shrimp, and so on

|

The machine adopts the newly developed forced convection process to carry out the cooking of shrimp at 85℃. This machine is designed for steaming boiled shrimp to the bottom of the tray. 1. Use high-temperature steam injection technology to maintain nutrients such as products. 2. It is equipped with a water sealing device to prevent steam leakage and good energy saving. 3. The controllability and uniformity of processing temperature are stronger, which can better guarantee product quality 4.Turbo fan circulates high temperature steam evenly throughout the area 5. All processing temperatures and internal product temperature are balanced, and the yield is significantly improved. 6, retain more water-soluble ingredients, cooked shrimp taste better. |