-

Shrimp Deheading Machine

-

Shrimp Peeling Machine

-

Shrimp Grading Machine

-

Fish Grading Machine

-

Shrimp Cooking Machine

-

Shrimp Cutting Machine

-

Shrimp Cleaning Machine

-

Fish Skinning Machine

-

Fish Cutting Machine

-

Fish Slicing Machine

-

Fish Gutting Machine

-

Fish Washing Machine

-

Fish Scaling Machine

-

Basket Washing Machine

-

Soaking Machine

-

Shrimp Processing Machine

-

Fish Processing Machine

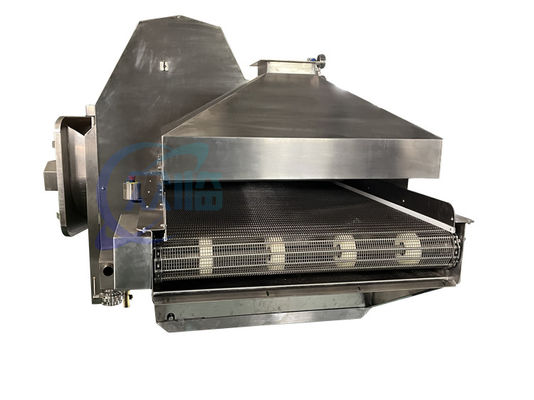

Multipurpose Shrimp Cooking Machine Automatic Anti Corrosion

| Keyword | Fan Work Shrimp Automatic Cooking Shrimp Automatic Cooker Tunnel Cooker | MOQ | 1 Set |

|---|---|---|---|

| Dimension(L*W*H) | L11000xW2200xH2000mm | Production Capacity | 500-700KG/H |

| Power | 18.2KW | Voltage | 380v/3p/50Hz |

| Number Of Zone | 4 | Operator | 4-5 Persons |

| Speed | Frequency | ||

| Highlight | Multipurpose Shrimp Cooking Machine,Shrimp Cooking Machine Automatic,Anti Corrosion Shrimp Automatic Cooker |

||

Fan Work Shrimp Automatic Cooking Shrimp Automatic Cooker Tunnel Cooker

|

The shrimp automatic cooking machine is a machine that uses the wind blown out by a fan to make the shrimp inside cook more fully and evenly. The steam can be automatically turned off or replenished according to the actual demand. Compared to traditional cooking machines, it achieves maximum energy conservation and consumes only 1/3 of the traditional diesel fuel consumption The cooked shrimp is more evenly cooked, the color is more beautiful, and the taste is more delicious The machine adopts the newly developed forced convection process to carry out the cooking of shrimp at 85℃. This machine is designed for steaming boiled shrimp to the bottom of the tray. 1. Use high-temperature steam injection technology to maintain nutrients such as products. 2. It is equipped with a water sealing device to prevent steam leakage and good energy saving. 3. The controllability and uniformity of processing temperature are stronger, which can better guarantee product quality 4.Turbo fan circulates high temperature steam evenly throughout the area 5. All processing temperatures and internal product temperature are balanced, and the yield is significantly improved. |