-

Shrimp Deheading Machine

-

Shrimp Peeling Machine

-

Shrimp Grading Machine

-

Fish Grading Machine

-

Shrimp Cooking Machine

-

Shrimp Cutting Machine

-

Shrimp Cleaning Machine

-

Fish Skinning Machine

-

Fish Cutting Machine

-

Fish Slicing Machine

-

Fish Gutting Machine

-

Fish Washing Machine

-

Fish Scaling Machine

-

Basket Washing Machine

-

Soaking Machine

-

Shrimp Processing Machine

-

Fish Processing Machine

3KW Durable Shrimp Peeling Machine Flexible 380V For Cleaning

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Keyword | Hot Sale Prawn Cleaning Machine Shrimp Peeling Machine Prawn Peeler | Warranty Of Core Components | 1 Year |

|---|---|---|---|

| Dimension(L*W*H) | L3600xW2260xH2200mm | Production Capacity | 250-300KG/H |

| Power | 3KW | Weight | 1200KG |

| Highlight | 3KW Shrimp Peeling Machine,Durable Shrimp Peeling Machine,Flexible Prawn Cleaning Machine |

||

Hot Sale Prawn Cleaning Machine Shrimp Peeling Machine Prawn Peeler

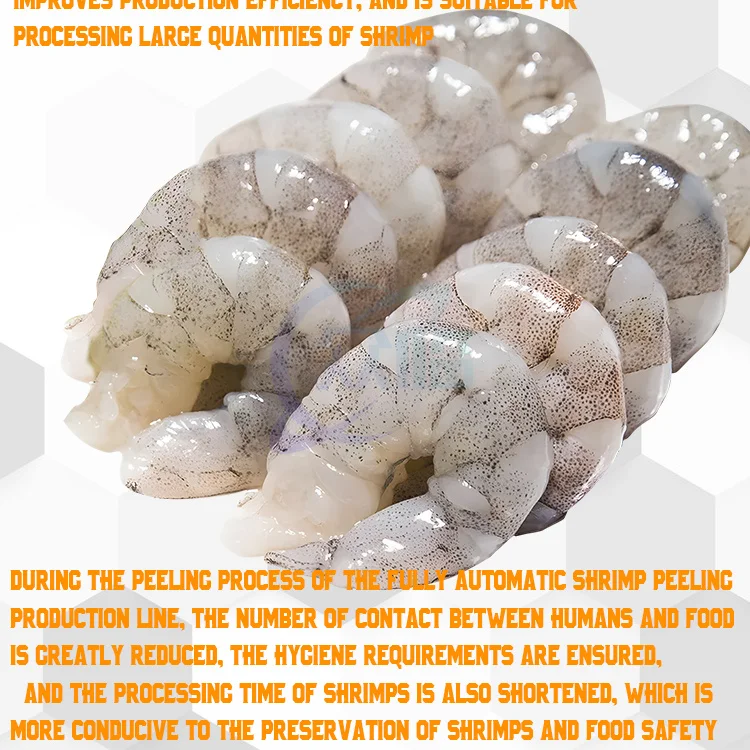

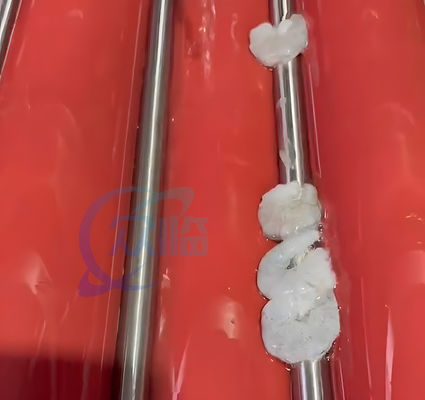

The shrimp peeler is composed of several single machines, mainly used for the processing of shrimp shelling. After cleaning, separation, decontamination, stripping, shrimp line, inspection and other processes.

The equipment has compact design, reasonable structure and small floor space, which improves the utilization rate of the production workshop; High degree of automation, open structure design, easy to clean, easy to operate and maintain, is the ideal processing equipment for modern large and medium-sized shrimp food processing enterprises

Our shrimp peeling machine have many advantage:

1. Faster: It is 30 times faster than manual peeling, and the efficiency is high;

2. Better: The effect of machine shelling is comparable to manual labor and the meat harvest rate is higher.

3. Lower cost: machine shelling replaces a large number of workers, reducing labor costs; small area occupied;

4. Safer: machine processing reduces the number of people's contact with food, shortens the processing time of shrimp, and is more conducive to shrimp preservation and food safety.

5. More flexible: the number of shell removes can be operated according to the output demand. There is no need to worry about the production difference caused by low and peak seasons, which makes the production plan more flexible.