-

Shrimp Deheading Machine

-

Shrimp Peeling Machine

-

Shrimp Grading Machine

-

Fish Grading Machine

-

Shrimp Cooking Machine

-

Shrimp Cutting Machine

-

Shrimp Cleaning Machine

-

Fish Skinning Machine

-

Fish Cutting Machine

-

Fish Slicing Machine

-

Fish Gutting Machine

-

Fish Washing Machine

-

Fish Scaling Machine

-

Basket Washing Machine

-

Soaking Machine

-

Shrimp Processing Machine

-

Fish Processing Machine

ISO Vegetable Fish Washing Machine Multipurpose Stainless Steel

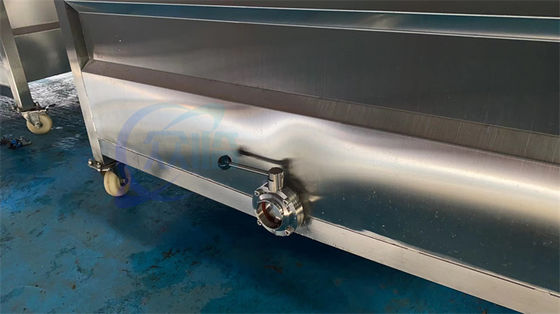

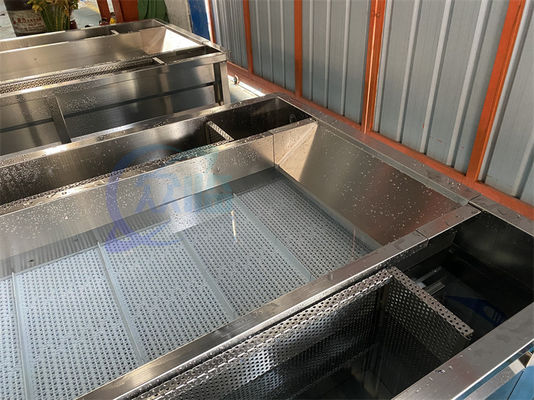

| Key Word | Smart Washing Machine For Seafood Fruit Vegetable Processing Spray Washing Machine | Material | Stainless Steel 304 |

|---|---|---|---|

| Dimension(L*W*H) | L4200xW1600xH1208mm | Production Capacity | 1000kg-1508kg |

| Power | 2.28KW | Weight | 508 KG |

| Highlight | ISO Fish Washing Machine,Fish Washing Machine Multipurpose,Stainless Steel Vegetable Washing Machine |

||

Smart Washing Machine For Seafood Fruit Vegetable Processing Spray Washing Machine

Spray washing machine introduction: bubble cleaning machine The whole machine is made of national high-quality SUS304 stainless steel, which meets the national food export standard. Food-grade materials are safe, reliable and pollution-free. The transportation is stable, the speed is adjustable, and the materials move along with the conveyor belt, which can avoid the damage to the transported materials. With low noise, it is suitable for quiet working environment. Simple structure and easy maintenance. Low energy consumption and low use cost. The cleaning machine adopts water bath bubble cleaning. The material in the water will have an irregular and strong turning motion through the churning effect generated by bubbles in the release process. The attachments on the surface of the object to be cleaned will be effectively separated through the movement of the material, and the basic action of manual cleaning will be simulated. At the same time, because the material is churning in the steam-water mixture, the material damage caused by bumping, knocking and scratching in the cleaning process can be effectively avoided, the work efficiency is improved, and the manual operation is changed into mechanical processing. Suitable for all kinds of fresh fruits, vegetables and fungi. In the process of conveying materials, the cleaning machine adds the spray cleaning function, so that the materials will be cleaned by spray after the steam-water bath cleaning. The function of this procedure is to replace and remove the dirty water on the surface of the materials, so as to improve the cleaning effect of the materials. At the same time, after the external cleaning spray water cleans the materials for the second time, the water will automatically flow into the water bath, so as to replace and supplement the cleaning water in the water bath, keep the cleanliness of the water in the water bath, not only improve the utilization rate of the cleaning water, but also increase